- AA,C,B

- BA,B,C

Describe Dynamics 365 Supply Chain Management - Quiz

- AWarehouse management

- BService management

- CCost management

- DAsset management

- ACreate a production process.

- BCreate a purchase order.

- CCreate service agreements.

- DGenerate master planning.

- Afirst in, first out (FIFO)

- Bstandard cost

- Clast in, first out date (LIFO Date)

- Dweighted average

- Amake-to-stock

- Bmake-to-order

- Cengineer-to-order

- Dconfigure-to-order

- AWave templates

- BLocation profiles

- CWork templates

- DWarehouse app event processing

- ADynamics 365 Finance

- BDynamics 365 Human Resources

- CDynamics 365 Project Operations

- DDynamics 365 Supply Chain Management

- AMake to stock

- BMake to order

- CConfigure to order

- DEngineer to order

Results:

🟢 Correct Answers: 🔴 Wrong Answers:

🟢 Correct Answers: 🔴 Wrong Answers:

Login to save results

Quiz Information

Quiz Information

Quiz Platform FAQ

General Information

- Number of Questions: Each quiz consists of 10 questions.

- Time Limit: You have 30 seconds per question. The total time to complete the quiz is 5 minutes.

- Multiple Attempts: You can take the quiz multiple times to improve your score.

Results and Feedback

- Result Analysis: After completing the quiz, you will see a results page with the following details:

- Correct Option for each question.

- Your Selected Option for each question.

- Explanation for each answer to help you understand why it is correct or incorrect.

- Percentage of Correct Answers to show your overall performance.

- Interactive Features: The platform provides feedback on each attempt to help you learn and improve.

Important Instructions

- Do Not Refresh: Do not refresh the page while taking the quiz. Refreshing the page will end the current quiz and a new quiz will start.

- Saving Your Quiz: To save your quiz progress and questions, log in to your account. Once logged in, you can view saved quizzes in your profile section.

- Mandatory Selection: All questions are mandatory to select. If you do not select all 10 questions, you will not be able to submit the quiz. Once all questions are selected, you will be able to see the Submit button. If you wait until the end of the time, the quiz will be auto-submitted by the system, and you will be able to see your results.

Tips for Taking the Quiz

- Manage Your Time: Keep track of the time for each question to ensure you have enough time to answer all 10 questions.

- Review Explanations: After the quiz, read the explanations provided for each answer to enhance your understanding of the material.

- Retake the Quiz: If desired, take the quiz again to improve your score and reinforce your learning.

- Avoid Refreshing: To prevent losing progress, avoid refreshing the page during the quiz.

- Log In to Save: If you want to save your quiz progress, log in to your account and check your profile section for saved quizzes.

Quiz Analytics

Describe Dynamics 365 Supply Chain Management - Quiz

Guest User Time Taken:

Time Taken: Questions: Answered: Not Answered:

Correct Answer:

Correct Answer:

Wrong Answer:

Wrong Answer:

Percentage: %

Percentage: %

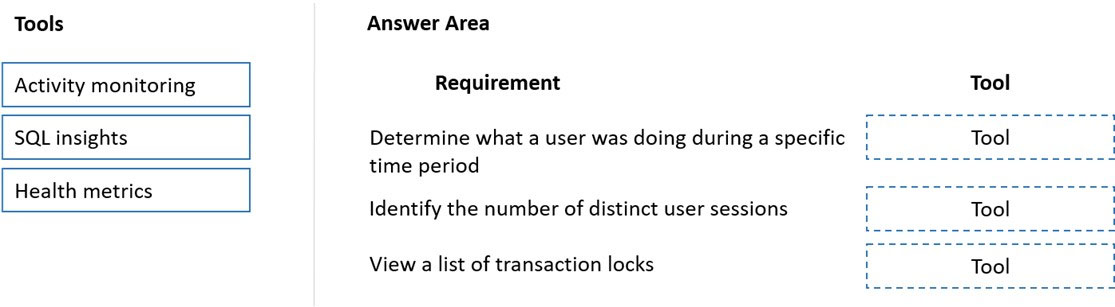

- A. A,C,B

- B. A,B,C

Remarks:

Explanation: Reference:

https://docs.microsoft.com/en-us/dynamics365/fin-ops-core/dev-itpro/lifecycle-services/monitoring-diagnostics https://docs.microsoft.com/en-us/dynamics365/fin-ops-core/dev-itpro/lifecycle-services/performancetroubleshooting

- A. Warehouse management

- B. Service management

- C. Cost management

- D. Asset management

Remarks:

Explanation:

This item tests the candidate's knowledge of the different modules in Dynamics 365 Supply Chain Management and the function that each one performs.

The company must configure the Warehouse management module. As part of the process for enabling a warehouse layout, you must define warehouse zone groups, zones, location profiles, location types, and locations. Asset management is an advanced module for managing assets and maintenance jobs in Dynamics 365 Supply Chain Management. The Cost management module lets you collect data from various sources, such as the general ledger, sub-ledgers, budgets, and statistical information. The cost data can then be analyzed, summarized, and evaluated so that management can make the best possible decisions for price updates, budgets, and cost control. The Service management module is used to establish service agreements and service subscriptions, handle service orders and customer inquiries, and to manage and analyze the delivery of services to customers.

Set up warehouse management - Training | Microsoft Learn

Warehouse configuration overview - Supply Chain Management | Dynamics 365 | Microsoft Learn

- A. Discrete

- B. Process

- C. Lean

Remarks:

Explanation:

This item tests the candidates’ knowledge of manufacturing strategies.

Process manufacturing is a production method that creates goods by combining supplies, ingredients, or raw materials using a formula or recipe. It is often used in industries that produce bulk quantities of goods, such as food, beverages, refined oil, gasoline, pharmaceuticals, chemicals, and plastics. Discrete manufacturing is a production of distinct items, where the resulting products are easily identifiable. This type is often used in industries like automobile, computers, and smartphones. Lean manufacturing is a production process based on an ideology of maximizing productivity while simultaneously minimizing waste within a manufacturing operation. The lean principle sees waste as anything that does not add value that the customers are willing to pay for.

Explore manufacturing strategies - Training | Microsoft Learn

Manage subcontracting work in production - Supply Chain Management | Dynamics 365 | Microsoft Learn

Lean manufacturing overview - Supply Chain Management | Dynamics 365 | Microsoft Learn

Production process overview - Supply Chain Management | Dynamics 365 | Microsoft Learn

- A. Create a production process.

- B. Create a purchase order.

- C. Create service agreements.

- D. Generate master planning.

Remarks:

Explanation:

This item tests the candidate’s knowledge of master planning. Master planning allows companies to determine and balance the future need for raw materials and capacity to meet company goals and is part of the manufacturing strategy.

The master planning process checks the demand, calculates the raw material requirements, and creates planned purchase orders accordingly. The production process describes the various stages of production orders, batch orders, and Kanbans, from order creation to closing of the financial period. A purchase order is something you would receive from a vendor, not something you would create when making a purchase. Service agreements are used to group service agreements by, for example, company size, geographical location, or industry type.

Master planning considerations and setup - Training | Microsoft Learn

Master planning home page - Supply Chain Management | Dynamics 365 | Microsoft Learn

- A. first in, first out (FIFO)

- B. standard cost

- C. last in, first out date (LIFO Date)

- D. weighted average

Remarks:

Explanation:

This item tests the candidate’s knowledge of the cost management methods available in Dynamics 365 Supply Chain Management to manage and track inventory costs, including standard and actual costs. The correct method of using the weighted average cost takes the average of the items that are received into inventory during the inventory closing process. First in, first out (FIFO) and last in, first out date (LIFO Date) are methods based on first and last receipt issuance respectfully. The standard costing method can support a standard cost inventory model for items, where the costing version has a set of standard cost records about items and manufacturing processes.

- A. make-to-stock

- B. make-to-order

- C. engineer-to-order

- D. configure-to-order

Remarks:

Explanation:

This item tests the candidate’s knowledge of the different manufacturing strategies available in Dynamics 365 Supply Chain Management that companies use to produce goods efficiently and effectively while meeting market demands and optimizing resources.

Describe manufacturing strategies - Training | Microsoft Learn

Production process overview - Supply Chain Management | Dynamics 365 | Microsoft Learn

- A. Wave templates

- B. Location profiles

- C. Work templates

- D. Warehouse app event processing

Remarks:

Explanation:

This item tests the candidate’s knowledge of determining limits of inventory in a warehouse.

Location profiles can create logical or physical groupings of locations that have the same warehouse location process policies (for example, a mix of different item numbers can be stored there, and the same physical capacity constraints apply). Wave templates help enable the outbound "Release to warehouse" process. Work templates define which work is performed and how the work is done in the warehouse. Batch jobs running in Dynamics 365 Supply Chain Management can use data from a queue for processing events issued by the Warehouse management mobile app to react as needed to the signaled events.

Explore warehouse configuration options - Training | Microsoft Learn

Warehouse configuration overview - Supply Chain Management | Dynamics 365 | Microsoft Learn

- A. Dynamics 365 Finance

- B. Dynamics 365 Human Resources

- C. Dynamics 365 Project Operations

- D. Dynamics 365 Supply Chain Management

Remarks:

Explanation:

This item tests the candidate’s knowledge of the available Dynamics 365 finance and operations apps and the function each app performs in enterprise resource planning (ERP).

The Dynamics 365 Human Resources app is primarily used to connect people and operations data together to help optimize workforce costs and take care of employees. In the scenario, the company can use the Personnel management workspace in Dynamics 365 Human Resources to meet the requirements. The Personnel Management workspace contains personnel movements, employee changes, open positions, address changes, expiring records, and analytics. Dynamics 365 Project Operations is incorrect because the app is used to manage projects and project delivery. Dynamics 365 Finance is incorrect because the app is used to control finances, manage funds, and conduct financial planning and forecasting. Dynamics 365 Supply Chain Management is incorrect because the app is used to manage a company's inventory, warehouses, manufacturing, services, and logistics while helping to build a resilient supply chain.

Get introduced to the finance and operations apps - Training | Microsoft Learn

- A. Make to stock

- B. Make to order

- C. Configure to order

- D. Engineer to order

Remarks:

Explanation:

This item tests the candidate’s knowledge of manufacturing strategies.

The make-to-stock principle is the classic manufacturing principle where you produce products for stock based on forecast or minimum stock refill. You calculate the latter based on forecast or historic consumption. The make-to-order principle is triggered by a sales order or transfer order. The configure-to-order principle is triggered by a sales order or transfer order. The actual product variant you produce is not predefined; you create it at the time of order entry based on the configuration model of the sales product. Engineer to order processes is typically addressed by a project and usually start with the engineering phase. During the engineering phase, the actual products that are required to fulfill the order are designed and described. Production orders, batch orders, or Kanbans can then be created to produce the products.

Explore manufacturing strategies - Training | Microsoft Learn

Production process overview - Supply Chain Management | Dynamics 365 | Microsoft Learn

- A. piece

- B. over-picking

- C. zone

- D. cluster

Remarks:

Explanation:

This item tests the candidate’s knowledge of the fulfilment process in Dynamics 365 Supply Chain Management and specifically identifying the different picking methods available to workers fulfilling orders in a warehouse. Cluster picking is the correct answer as workers use a mobile device to assign orders to a cluster. This allows them to pick items for multiple orders simultaneously by clustering them into pick clusters and minimize warehouse travel time. Piece picking is not optimized for collecting multiple orders in one go. Over-picking relates to workers over-picking slightly more material than is specified for a production order. Zone picking applies when workers are assigned to a specific zone or region of the warehouse.

Piece picking confirmation - Supply Chain Management | Dynamics 365 | Microsoft Learn

Warehouse configuration overview - Supply Chain Management | Dynamics 365 | Microsoft Learn